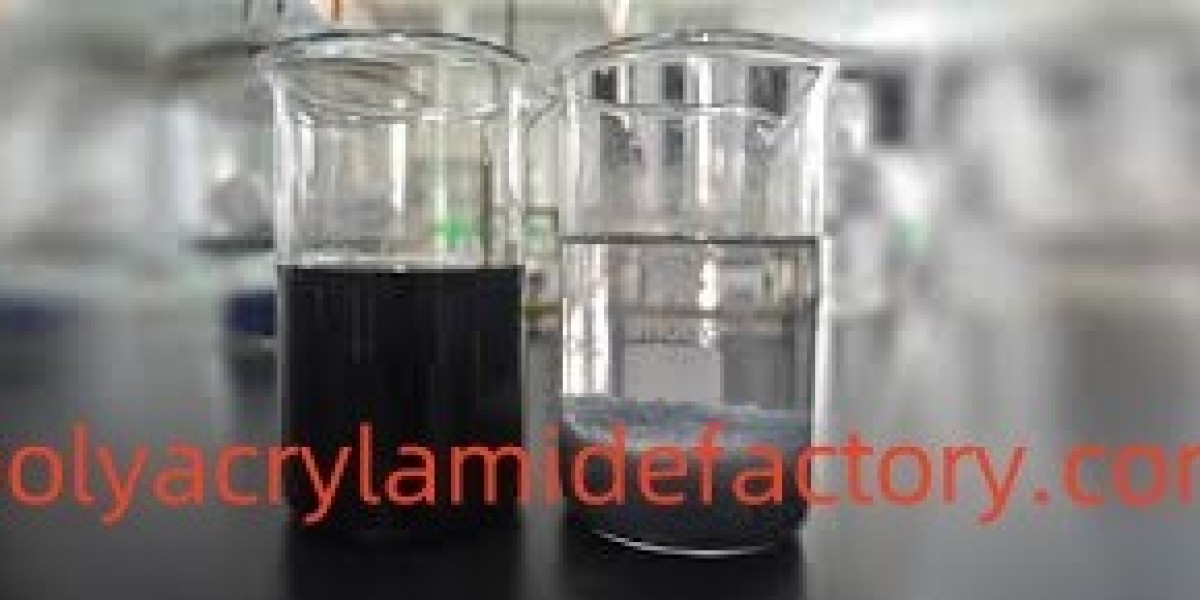

As a trusted leader among mineral processing flocculant Manufacturers , we deliver innovative solutions designed to optimize efficiency, sustainability, and profitability in your operations. Our advanced flocculant chemistries empower industries to overcome challenges in tailings management, water recovery, and solid-liquid separation, ensuring faster sedimentation, higher throughput, and reduced environmental impact.

Why Choose Us?

Our tailored flocculants are engineered for diverse mineral processing needs. With formulations spanning anionic, cationic, and non-ionic options—available as powders, liquid emulsions, or beads—we provide precise solutions to enhance aggregation efficiency. Backed by cutting-edge monitoring systems, including automated dosing and cloud-based analytics, we ensure consistent performance and operational stability.

Comprehensive Support

Beyond products, our expertise extends to laboratory testing, on-site diagnostics, and customized application strategies. Whether optimizing underflow clarity or improving dewatering rates, our technical team collaborates closely with clients to deliver measurable results.

Sustainability-Driven Innovation

We prioritize eco-friendly practices, offering solutions that minimize waste and maximize water reuse. By integrating high-performance flocculants with smart resource management, we help clients align with global sustainability standards while reducing operational costs.

Visit https://www.polyacrylamidefactory.com today to explore how our expertise can elevate your mineral processing outcomes.