Unlocking the Secrets of ABS Filament: Your Ultimate Guide to 3D Printing Mastery!

In the rapidly evolving world of 3D printing, the choice of materials can make all the difference in the success of your projects. Among the many options available, ABS filament stands out as a popular choice for both hobbyists and professionals. Known for its versatility and robustness, ABS filament has become a staple in the 3D printing community. This article aims to unravel the complexities of ABS filament, exploring its characteristics, advantages, disadvantages, and diverse applications. As 3D printing continues to gain traction across various industries, understanding the materials you work with is essential for achieving outstanding results.

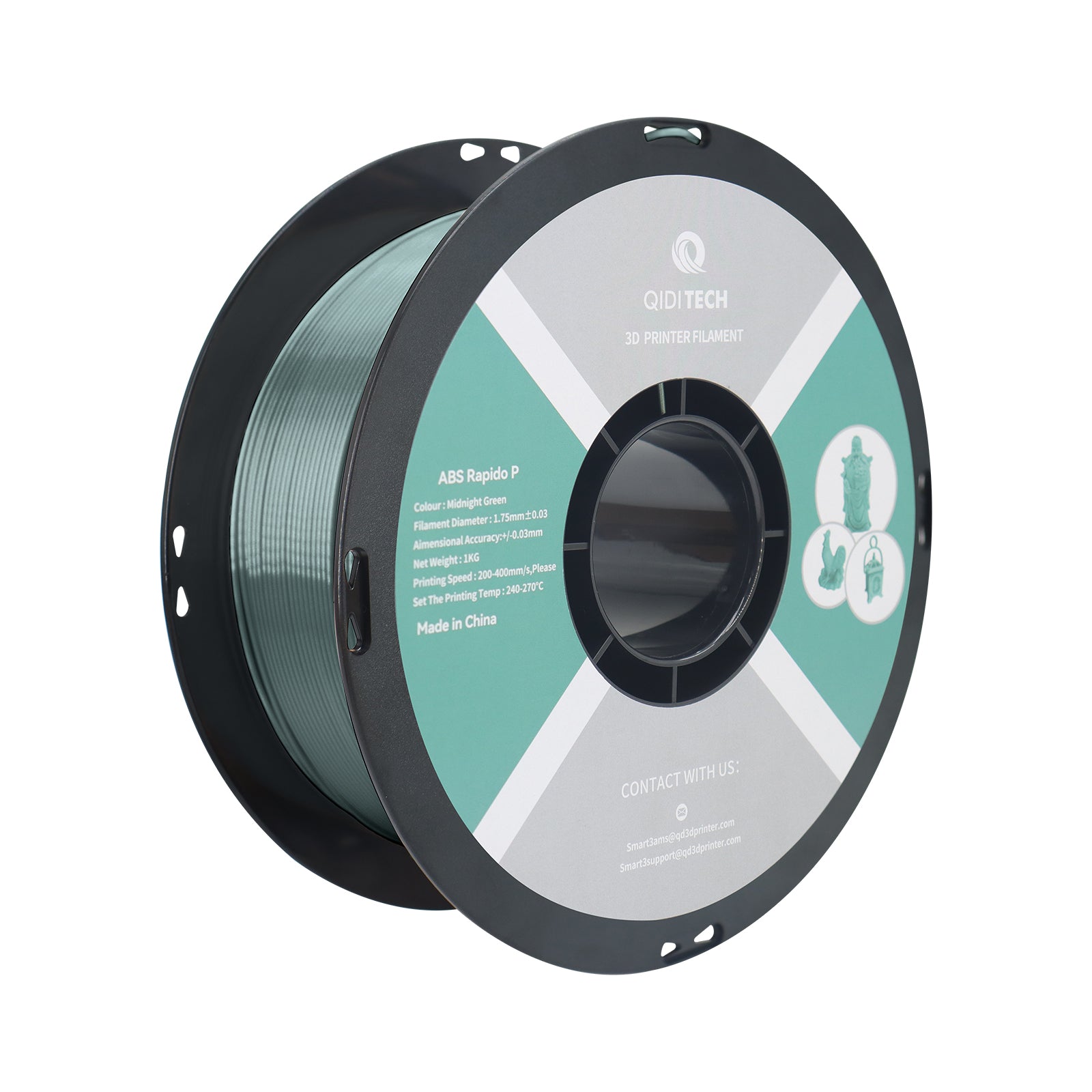

What is ABS Filament?

ABS filament, short for Acrylonitrile Butadiene Styrene, is a thermoplastic commonly used in 3D printing due to its unique properties. First introduced in the 1950s, ABS quickly gained popularity in various manufacturing processes, particularly for creating robust and durable products. In the realm of 3D printing, it is favored for its ease of use and ability to produce high-quality prints. The chemical composition of ABS consists of three monomers: acrylonitrile, butadiene, and styrene. This combination results in a material that is not only strong but also flexible and resistant to impact, making it ideal for a wide range of applications. The production of ABS filament involves extrusion, where the raw materials are melted and formed into a filament suitable for 3D printing.

Characteristics of ABS Filament

ABS filament is celebrated for several key properties that enhance its performance in 3D printing. One of its most significant characteristics is its strength; ABS parts are known to withstand substantial stress and strain, making them less prone to breaking under pressure. Furthermore, its durability allows for long-lasting products that can endure daily wear and tear. Flexibility is another notable attribute; while ABS is strong, it can also bend without fracturing, a feature that is particularly beneficial for creating intricate designs. Additionally, ABS filament boasts excellent temperature resistance, maintaining its shape and integrity even when exposed to heat. These characteristics collectively contribute to its popularity among 3D printing enthusiasts, as they facilitate the production of high-quality, resilient prints.

Advantages and Disadvantages of Using ABS Filament

Like any material, ABS filament comes with its own set of advantages and disadvantages. On the positive side, one of the primary advantages of using ABS is its ease of printing. It adheres well to the print bed and is less prone to warping compared to other materials, making it a great choice for beginners. Additionally, ABS supports post-processing techniques such as sanding and acetone vapor smoothing, enabling users to achieve a polished finish on their prints. However, there are also drawbacks to consider. ABS filament emits fumes during printing that can be unpleasant and potentially harmful if inhaled, so proper ventilation is crucial. Moreover, the material can be more challenging to print in intricate designs due to its tendency to warp if not managed properly. Environmental considerations also arise, as ABS is derived from petroleum-based sources, raising concerns about sustainability.

Applications of ABS Filament in 3D Printing

The applications of ABS filament in 3D printing are vast, making it suitable for various industries. In the automotive sector, for instance, ABS is often used to create prototypes of car parts due to its strength and durability. This allows engineers to test designs before committing to production, saving time and resources. In consumer products, ABS is frequently employed in the manufacturing of toys, household items, and electronic housings, thanks to its ability to withstand daily use. Additionally, ABS filament is a favorite among hobbyists and designers for prototyping, allowing for rapid development of innovative ideas. The benefits of using ABS in these applications are clear; it not only provides a reliable and robust solution but also accelerates the design and production process, making it an invaluable material in the world of 3D printing.

Key Takeaways on ABS Filament

Understanding ABS filament is essential for anyone looking to excel in the realm of 3D printing. From its robust characteristics to its wide array of applications, ABS offers a versatile and reliable option for both new and experienced users. The knowledge gained from this article can empower you to make informed decisions in your printing projects, enabling you to harness the full potential of this remarkable material. So, whether you're designing prototypes, creating consumer products, or simply exploring your creativity, don't hesitate to experiment with ABS filament in your next 3D printing endeavor. The possibilities are endless!