Unlock Your Creativity: Discover the Secrets to Choosing the Perfect ABS Filament for Stunning 3D Prints!

In the ever-evolving world of 3D printing, the choice of filament is crucial to unlocking your creative potential. Among the myriad options available, ABS filament stands out for its versatility and durability, making it a favorite among hobbyists and professionals alike. As 3D printing grows in popularity, the importance of selecting the right filament to achieve desired results cannot be overstated. Whether you’re crafting intricate models, functional prototypes, or decorative pieces, understanding the nuances of ABS filament can significantly enhance your 3D printing experience.

Understanding ABS Filament

ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer known for its strength, flexibility, and impact resistance. These properties make it an excellent choice for a wide range of 3D printing applications, from automotive components to consumer products. The filament is characterized by its glossy finish and vibrant colors, allowing for aesthetically pleasing prints that catch the eye. Additionally, ABS is relatively easy to work with, offering good layer adhesion and the ability to be smoothed with acetone vapor, which can enhance the surface finish of your prints. This combination of attributes has made ABS a go-to material for many 3D printing enthusiasts, providing the perfect balance between usability and performance.

Factors to Consider When Choosing ABS Filament

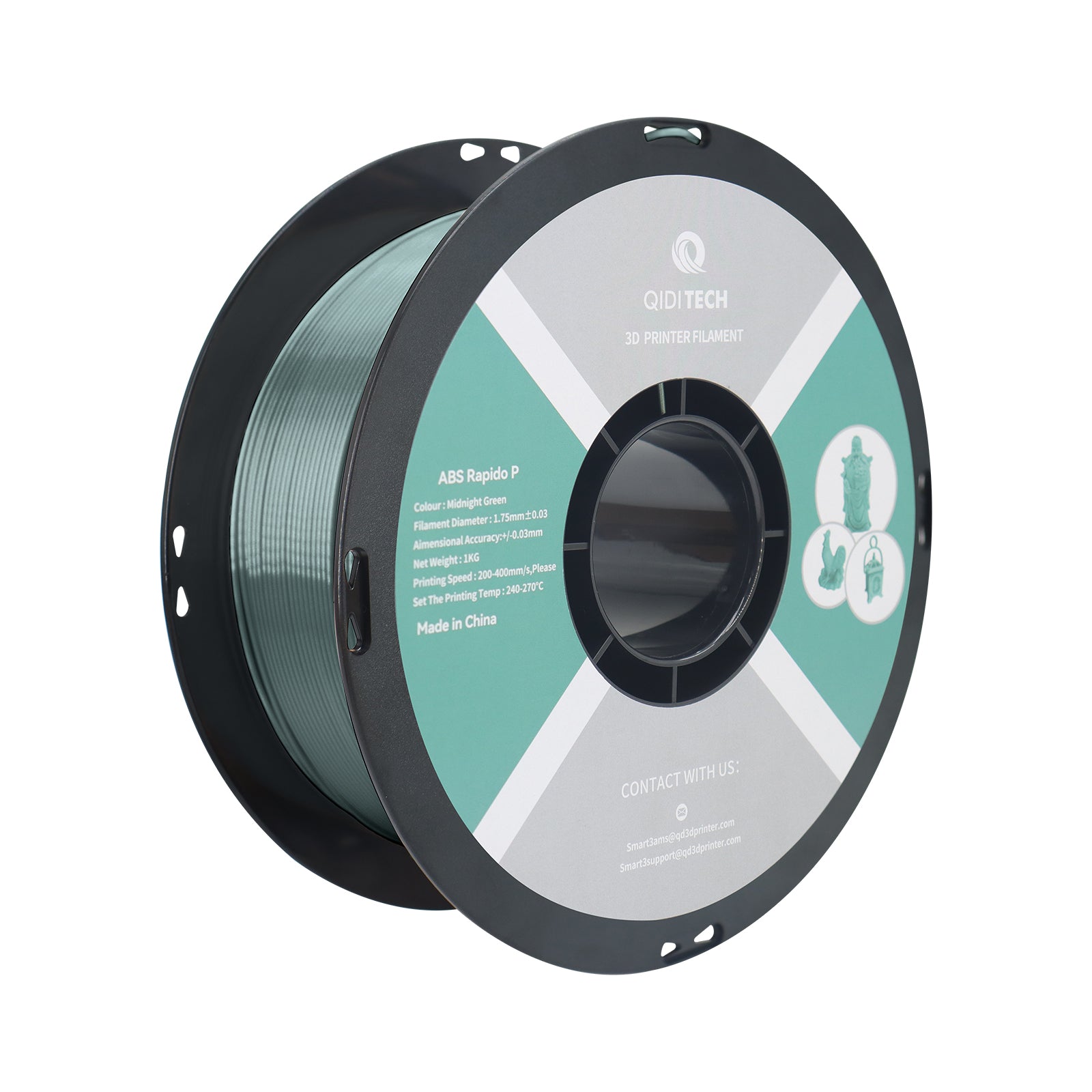

When diving into the world of ABS filament, it’s essential to consider several key factors that can influence your printing experience. First, color options play a significant role in determining the aesthetic appeal of your final product. ABS is available in a wide range of colors, allowing you to choose the perfect shade for your project. Second, the diameter of the filament—commonly 1.75 mm or 2.85 mm—must be compatible with your 3D printer’s specifications. Using the incorrect diameter can lead to clogs or uneven extrusion. Finally, the melt temperature of ABS typically ranges from 210°C to 250°C, so understanding your printer's capabilities and the printing environment, including the need for a heated bed, is crucial for achieving optimal results.

Color and Aesthetic Choices

The variety of colors available in ABS filament can greatly affect the final appearance of your prints. From bold reds and blues to subtle pastels, the color choice can enhance the visual impact of your creations. My friend, who runs a small 3D printing business, often experiments with different colors to create unique designs that stand out in a saturated market. This creativity not only attracts customers but also allows him to express his artistic flair.

Diameter and Compatibility

Choosing the correct diameter for your ABS filament is vital for compatibility with your 3D printer. Most printers are designed to work with either 1.75 mm or 2.85 mm filament, and selecting one that fits your printer’s specifications is essential. Using the wrong diameter can lead to printing issues, such as inconsistent extrusion or even jams, which can be frustrating for anyone trying to complete a project.

Melt Temperature and Printing Environment

ABS filament requires a melt temperature typically between 210°C and 250°C. Additionally, the printing environment is crucial; using a heated bed can help prevent warping and improve adhesion. For instance, I recall a time when I printed a complex design without a heated bed, and the corners of my print curled up, ruining the entire piece. Ensuring your printer is set up correctly can save you time and material in the long run.

Common Issues and How to Overcome Them

Despite its many advantages, working with ABS filament can come with its own set of challenges. One of the most common issues is warping, which occurs as the filament cools and contracts. To mitigate this, using a heated bed and ensuring proper bed adhesion can make a significant difference. Additionally, ensuring your print environment is draft-free can help maintain a consistent temperature. Another frequent challenge is adhesion issues, where layers do not stick together properly. Using an appropriate adhesive on the print bed or adjusting the first layer settings can enhance adhesion and lead to more successful prints. By being aware of these potential problems and implementing preventative measures, you can create high-quality prints with ABS filament.

Final Thoughts on ABS Filament Selection

In conclusion, selecting the right ABS filament is a critical step in achieving stunning 3D prints that reflect your creativity and technical skills. By understanding the properties of ABS, the factors to consider when choosing filament, and the common issues you may encounter, you can enhance your 3D printing projects significantly. Don’t hesitate to explore different colors, diameters, and settings to find what works best for you. Embrace the process, experiment with your designs, and let your creativity shine through your 3D prints!