Unlocking Solar Secrets: The Ultimate Journey Through Industrial Power Production!

As the world grapples with the pressing challenges of climate change and energy sustainability, solar power has emerged as a beacon of hope, particularly in industrial applications. The shift towards renewable energy sources is increasingly relevant for manufacturers aiming to reduce their carbon footprint and operational costs. This article delves into the intricate solar power manufacturing process tailored specifically for industrial projects, shedding light on the journey from raw materials to energy production. With insights into the technology behind solar energy and the challenges faced in the industry, readers will gain a comprehensive understanding of how solar power can transform manufacturing processes and contribute to a greener future.

Understanding Solar Power Manufacturing

Solar power manufacturing refers to the processes involved in creating solar technologies that convert sunlight into usable energy. This sector plays a significant role in the industrial landscape, especially as companies seek sustainable solutions to meet their energy demands. The basic principle of solar energy conversion lies in the photovoltaic effect, where sunlight is absorbed by materials and converted into electricity. There are various types of solar technologies available, including photovoltaic (PV) systems, concentrating solar power (CSP), and solar thermal systems, each with its unique applications and efficiencies. Understanding these technologies is crucial for industrial sectors looking to integrate solar solutions into their operations.

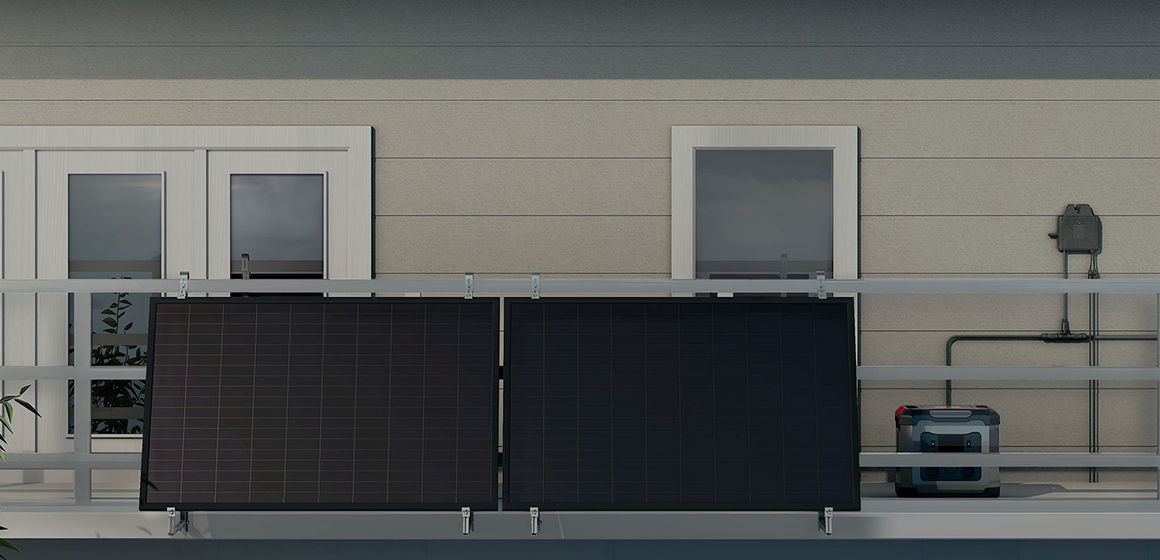

The Solar Power Manufacturing Process

The solar power manufacturing process is a multi-faceted journey that encompasses several key stages, from material selection to module assembly and quality control. Each step is crucial in ensuring that the final product meets the required performance standards and can withstand the rigors of industrial use. The manufacturing process begins with the selection of high-quality materials, which are then transformed into solar cells through intricate fabrication techniques. After the cells are produced, they are assembled into modules, followed by rigorous testing to ensure durability and efficiency. This process not only demands technical expertise but also a commitment to quality, as even minor defects can significantly impact performance.

Material Selection

Choosing the right materials is fundamental to the solar manufacturing process. The most common materials used in solar cells include silicon, cadmium telluride, and copper indium gallium selenide. Each material comes with its own set of properties that affect efficiency, cost, and environmental impact. For instance, silicon-based cells are renowned for their efficiency and durability, making them a staple in the industry. On the other hand, thin-film technologies, while less efficient, offer flexibility and lower manufacturing costs. Selecting high-quality materials not only contributes to better performance but also to the longevity of the solar panels, making it a critical step in the manufacturing process.

Cell Manufacturing and Module Assembly

The production of solar cells involves several complex steps, including doping, etching, and layering. These processes enhance the cells' ability to capture and convert sunlight into electricity. Once the cells are fabricated, they are assembled into modules, which involves connecting multiple cells together and encasing them in protective materials. This assembly process must adhere to strict manufacturing standards to ensure that the modules can withstand environmental stresses such as wind and hail. Quality control is paramount throughout this stage, as it ensures that each module meets the necessary performance criteria before reaching the market.

Challenges in Solar Power Manufacturing

Despite its promise, the solar power manufacturing industry faces several challenges. Supply chain issues, particularly in sourcing raw materials, can lead to delays and increased costs. Additionally, technological limitations, such as the efficiency of solar cells and the ability to produce them at scale, continue to pose hurdles for manufacturers. Environmental concerns also play a role, as the production processes can generate waste and emissions if not managed properly. To address these challenges, the industry is increasingly looking towards innovations in recycling technologies, alternative materials, and improved manufacturing techniques that minimize environmental impact while maximizing efficiency.

The Future of Solar Power in Industrial Projects

The future of solar power manufacturing holds exciting potential, driven by continuous technological innovations and growing market demand. Trends such as the development of more efficient solar cells, advancements in energy storage solutions, and the integration of smart grid technology are set to revolutionize how solar energy is harnessed and utilized in industrial settings. Furthermore, supportive government policies and incentives are encouraging manufacturers to adopt solar solutions, paving the way for a more sustainable energy landscape. As the industry evolves, it is anticipated that solar power will play an increasingly pivotal role in meeting the energy needs of various sectors, driving both economic growth and environmental sustainability.

Key Insights on Solar Power's Role in Industry

In summary, the journey through solar power manufacturing unveils a complex yet fascinating process that is vital for industrial applications. From material selection to module assembly, each stage is essential for creating efficient solar technologies that can meet the energy demands of modern manufacturing. The challenges faced by the industry are significant, but with ongoing innovations and a commitment to sustainability, the future of solar power in industrial projects looks bright. As businesses continue to explore renewable energy options, the potential of solar power stands out as a compelling solution worth considering for their operations.