Introduction

The landscape of industrial automation is undergoing a profound transformation, with technological advancements shaping the future of manufacturing. Among the innovative technologies driving this change, Time of Flight (ToF) sensors emerge as crucial components in the journey towards smart manufacturing. In this blog, we'll explore the impact of ToF sensors on industrial automation, examining how they contribute to efficiency, precision, and the evolution of smart factories.

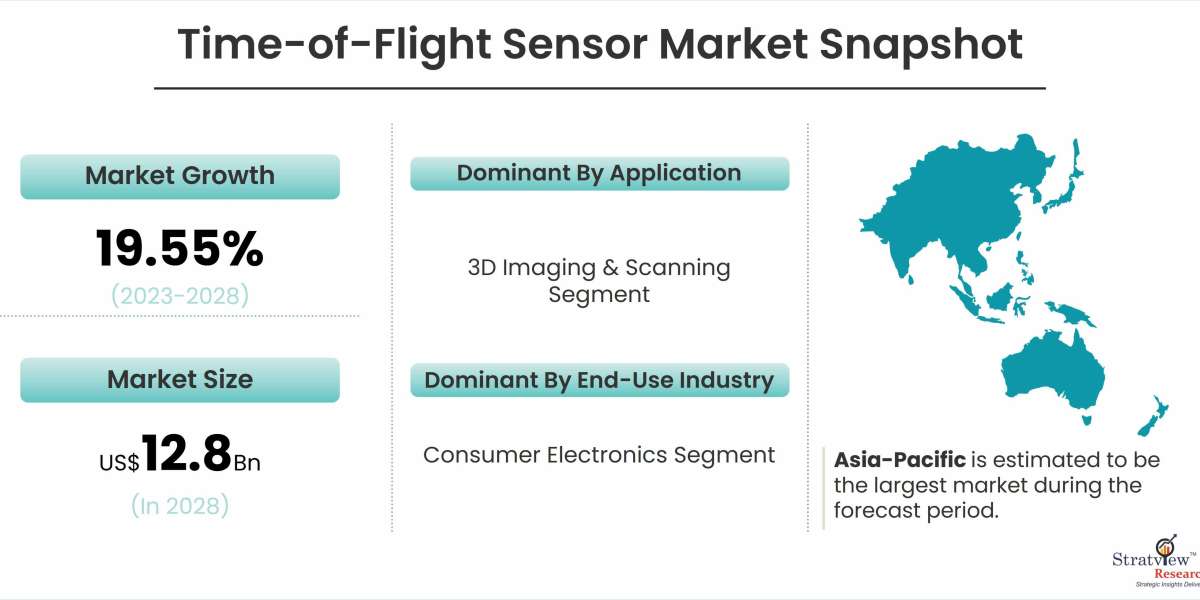

According to Stratview Research, The Global Time-of-Flight (ToF) Sensor Market is expected to grow from US$ 4.39 billion in 2022 to US$ 12.82 billion by 2028 at a healthy CAGR of 19.55% during the forecast period of 2022-2028.

Time-of-flight sensor is a remote sensing method, which uses an infrared light pulse to detect and measure distances very accurately by measuring the return time of pulse.

ToF sensor is a cost-effective technology that can measure long-range distances with high accuracy at a very fast rate. It has been used for a wide range of applications which can be classified into gesture and non-gesture.

To learn more about the report, click here:

https://www.stratviewresearch.com/1731/time-of-flight-(ToF)-sensor-market.html

Understanding Time of Flight Sensors

Before delving into their role in smart manufacturing, let's grasp the fundamentals of Time of Flight sensors. These sensors operate on the principle of measuring the time it takes for light to travel to an object and back. Emitting short pulses of light, ToF sensors calculate the time delay for the return, providing accurate distance measurements. This capability allows them to create detailed 3D maps of the environment, making them invaluable in industrial automation settings.

ToF Sensors in Object Detection and Collision Avoidance

One of the primary applications of ToF sensors in smart manufacturing is object detection and collision avoidance. In a factory setting with automated machinery and robotic systems, the ability to detect the presence and position of objects in real time is crucial for preventing collisions and ensuring the safety of both equipment and personnel.

ToF sensors provide a reliable solution for this challenge by offering precise distance measurements. Whether it's a robot navigating through a warehouse or a conveyor system managing the flow of materials, ToF sensors contribute to the creation of a safer and more efficient working environment.

Precision in Robotic Automation

Robotics is at the forefront of industrial automation, performing tasks with speed and precision. ToF sensors enhance the capabilities of robots by providing accurate depth perception. This enables robots to interact with their environment more intelligently, making them adept at tasks that require precise positioning and manipulation.

For example, in pick-and-place operations, ToF sensors assist robots in accurately identifying the location and orientation of objects. This level of precision is particularly valuable in industries such as electronics manufacturing, where small and delicate components require careful handling.

Optimizing Manufacturing Workflows

Smart manufacturing is all about optimizing workflows and processes for maximum efficiency. ToF sensors play a significant role in achieving this optimization by providing real-time data on the position and movement of objects within the manufacturing environment. This data can be used to streamline operations, reduce bottlenecks, and enhance overall productivity.

In a production line, ToF sensors can be employed to monitor the flow of materials and ensure that each component is in the right place at the right time. This level of automation contributes to the reduction of manual intervention, minimizing errors and improving the overall speed and accuracy of manufacturing processes.

Quality Control and Inspection

Ensuring product quality is a critical aspect of manufacturing. ToF sensors contribute to quality control processes by providing detailed 3D information that can be used for inspection purposes. In industries such as automotive manufacturing, where precision is paramount, ToF sensors assist in detecting defects, measuring dimensions, and ensuring that products meet the required specifications.

The ability of ToF sensors to create accurate depth maps is particularly valuable in inspecting complex and intricate components. From checking the alignment of parts to detecting surface imperfections, ToF technology enhances the capabilities of automated inspection systems.

Real-Time Monitoring and Maintenance

Smart manufacturing involves not only optimizing current processes but also anticipating and preventing issues before they occur. ToF sensors contribute to this proactive approach by enabling real-time monitoring of equipment and machinery.

By continuously assessing the position and condition of critical components, ToF sensors provide valuable data that can be used to predict potential issues. This predictive maintenance approach allows manufacturers to schedule maintenance activities based on actual equipment conditions rather than fixed schedules, reducing downtime and extending the lifespan of machinery.

Logistics and Material Handling

In a smart manufacturing environment, the efficient movement of materials and goods is essential. ToF sensors contribute to logistics and material handling by providing accurate distance measurements for automated guided vehicles (AGVs) and conveyor systems.

AGVs equipped with ToF sensors can navigate through warehouses and production facilities with precision, avoiding obstacles and optimizing their paths. This level of automation enhances the overall efficiency of material handling processes, from raw material intake to finished product delivery.

Energy Efficiency and Sustainability

Smart manufacturing also encompasses a commitment to sustainability and energy efficiency. ToF sensors contribute to these goals by optimizing the use of resources within a factory setting. For instance, they can be employed to control lighting and heating systems based on the occupancy of different areas, reducing energy consumption and environmental impact.

The detailed information provided by ToF sensors can also be utilized to analyze and optimize the overall layout of a manufacturing facility. By understanding how space is utilized and identifying areas of congestion or underutilization, manufacturers can design more efficient layouts that contribute to a greener and more sustainable operation.

Challenges and Future Developments

While ToF sensors offer significant advantages in smart manufacturing, challenges and opportunities for improvement exist. Calibration and environmental factors can affect the accuracy of distance measurements, and ongoing research is focused on addressing these issues. Additionally, advancements in sensor technology, along with improvements in data processing capabilities, are expected to enhance the precision and reliability of ToF sensors in industrial settings.

The integration of ToF sensors with other technologies, such as artificial intelligence and machine learning, holds the promise of creating more intelligent and adaptive manufacturing systems. These systems could learn from historical data, continuously optimize processes, and adapt to changing production requirements in real time.

Conclusion: The Evolution of Smart Factories

In conclusion, time-of-flight sensors are catalysts for the evolution of smart manufacturing, contributing to increased efficiency, precision, and automation. From object detection and collision avoidance to robotic automation, quality control, and logistics, ToF sensors play a pivotal role in shaping the future of industrial automation.

As smart factories continue to embrace digital transformation, the integration of ToF sensors opens up new possibilities for optimizing workflows, enhancing safety, and promoting sustainability. The journey towards smart manufacturing is a dynamic one, and Time of Flight sensors stand as indispensable tools in navigating the complexities of the modern industrial landscape. As technology advances and industries embrace the potential of these sensors, we can expect a future where smart factories redefine the limits of what is possible in manufacturing and automation.

About Us

Stratview Research is a global market research firm, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients insightful market data to aid strategic decision-making. These exclusive reports are the result of exclusive research methodology and are available for key industries such as chemicals, composites, advanced materials, technology, renewable energy, and more.

Stratview Research delivers custom research services across sectors. In case of any custom research requirements, please send your inquiry to [email protected] or connect with our experts at +1-313-307-4176.